How Do Steam Engines Work? A Comprehensive Guide to History, Mechanics, and DIY Models

Steam engines are the iron giants that powered the Industrial Revolution, transformed global transportation, and shaped the modern world. But for many, the rhythmic chugging and hissing of these machines remain a mystery.

Whether you are a student researching how a steam engine works, a history buff, or a hobbyist looking to build your own working steam engine kit, this guide covers everything you need to know. We will explore the history, the science, and finally, show you how to bring this technology to your desktop with a model steam engine.

1. What Is a Steam Engine?

At its simplest, a steam engine is a heat engine that performs mechanical work using steam as its working fluid.

Unlike the engine in your car, which burns fuel inside the cylinder (Internal Combustion), a steam engine burns fuel (like coal, wood, or gas) outside the engine to heat water in a separate boiler. For this reason, steam engines are classified as external combustion engines.

The Basic Concept:

Fuel creates heat→→Heat boils water→→Water turns to Steam (expanding 1,600x in volume)→→Pressure pushes a Piston→→Motion is created.

2. The History: From Ancient Toys to Industrial Titans

Before the internal combustion engine took over in the 20th century, steam was king. But the story begins much earlier than you might think.

Early Beginnings

The tale goes back to the 1st century AD with Hero of Alexandria. He invented the aeolipile, a spinning metal sphere powered by steam jets. While fascinating, it was considered a mere curiosity or toy, lacking practical use at the time.

In 1551, Taqi al-Din in Ottoman Egypt described a rudimentary steam turbine. However, the true race for steam power began in the 17th century to solve a specific problem: removing water from flooded mines.

The Pioneers

- 1698 (Thomas Savery): Created the first commercially used steam pump. It was simple but limited in power and dangerous due to high pressure.

- 1712 (Thomas Newcomen): The first true "atmospheric engine." It used steam to create a vacuum, allowing atmospheric pressure to push a piston down. It was reliable but incredibly inefficient because it wasted heat by constantly cooling and reheating the cylinder.

The Watt Revolution

The turning point came in 1765, when James Watt improved Newcomen’s design. Watt added a separate condenser, which allowed the cylinder to stay hot while the steam was condensed elsewhere. This single change drastically increased efficiency and power, making steam engines viable for factories, not just mines.

The Age of Locomotion

In the 1800s, engineers like Richard Trevithick pioneered high-pressure steam engines, which were small and powerful enough to move themselves. This led to George Stephenson’s "Rocket" (1829), the locomotive that set the standard for how a steam train engine works and ignited the railway era.

3. How Does a Steam Engine Work? (The Science)

To understand how do steam engines work, we must look at the thermodynamic process known as the Rankine Cycle. This is the continuous loop of turning heat into motion.

Key Components

Before looking at the cycle, here are the parts you need to know:

- Boiler: A pressure vessel where water is heated to become steam.

- Slide Valve: The "brain" of the engine that directs steam into the cylinder and lets exhaust out.

- Cylinder & Piston: The chamber where steam expands to push a sliding metal rod (piston).

- Connecting Rod & Crankshaft: Converts the linear (back-and-forth) motion of the piston into rotary (spinning) motion.

- Flywheel: A heavy wheel that carries momentum to keep the engine spinning smoothly.

The Working Mechanism (Step-by-Step)

Step 1: Isentropic Compression (The Pump)

The cycle starts with water in a liquid state. A pump forces water into the high-pressure environment of the boiler. Think of this like pumping air into a bicycle tire, but with water.

Step 2: Isobaric Heat Addition (The Boiler)

Inside the boiler, fuel is burned to heat the water at constant pressure. When water reaches boiling point (100°C+), it turns into steam.

- Science Fact: Steam occupies roughly 1,600 times more volume than liquid water. In a closed container, this expansion creates immense pressure, ready to do work.

Step 3: Isentropic Expansion (The Power Stroke)

This is where the magic happens. The high-pressure steam is released into the Cylinder.

- The steam expands and pushes the Piston forward with great force (F=ma).

- The piston pushes the connecting rod, which turns the Crankshaft.

- This converts thermal energy into mechanical energy.

Step 4: Isobaric Heat Rejection (The Exhaust)

After pushing the piston, the "spent" steam (which has lost some energy and pressure) is pushed out of the cylinder by the returning piston. It enters a Condenser, where it cools back down into liquid water, ready to be pumped back into the boiler to start the cycle again.

4. How Steam Changed the World: Common Uses

The application of steam power was the catalyst for modern civilization.

- Trains and Railways: Before steam, travel was limited by horse endurance. Steam train engines allowed passengers and heavy freight to cross continents in days rather than months, booming the global economy.

- Factories: Steam engines liberated factories from riverbanks (water wheels). They powered looms, saws, and lathes with consistent reliable power, enabling mass production.

- Ships: Unlike sailing vessels dependent on fickle winds, steamships could cross oceans on a schedule, revolutionizing international trade and naval warfare.

- Mining: Steam pumps allowed mines to go deeper than ever before by efficiently removing groundwater, accessing previously unreachable resources.

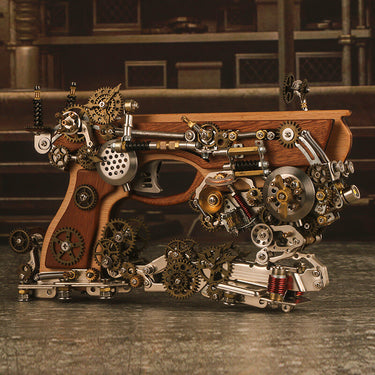

5. The Modern Hobby: Model Steam Engines & Kits

While giant steam locomotives are now mostly found in museums, the fascination with steam power lives on in the form of miniature steam engines.

For hobbyists, engineers, and educators, a working model of steam engine is the perfect way to see these principles in action. Unlike a closed box, these models are often "skeleton" designs, meaning you can see every piston stroke, valve movement, and flywheel rotation.

Why Build a Steam Engine Model?

- Educational: It is the best hands-on physics lesson you can get.

- Aesthetic: The combination of brass, steel, and mechanical motion makes for stunning desktop displays.

- Satisfaction: Building a machine that runs on fire and water provides a sense of accomplishment that digital gadgets cannot match.

6. How to Build Your Own Steam Engine (DIY Guide)

If you are asking, "Can I build one myself?" The answer is yes. Steam engine kits for adults and students have made this accessible.

At EngineDIY, we provide comprehensive kits that include everything you need—from the boiler to the tiniest screw—to assemble a fully functional engine.

Step-by-Step Assembly Tutorial

Here is a general guide on how to assemble a typical DIY steam engine kit.

Tools You May Need:

- Screwdrivers (Phillips and Flathead)

- Allen keys (usually included)

- Tweezers and Pliers

- Lubricating oil

The Assembly Process:

- Inventory Check: Unpack your kit and match every part against the manual. Do not lose the small O-rings or gaskets!

- Mount the Cylinder: Attach the cylinder block to the base plate. Insert the piston into the cylinder. Tip: Apply a drop of oil to the piston for smooth movement.

- The Crankshaft Assembly: Connect the piston rod to the crankshaft. Mount the flywheel to the crankshaft axle. Spin it by hand—it should rotate freely without any "grinding."

- Install the Boiler: Secure the boiler tank to the base using the provided brackets. Ensure it is elevated enough to fit the burner underneath.

- Plumbing: Connect the steam pipe (often transparent or copper) from the boiler's output to the cylinder's intake valve. Ensure seals are tight to prevent steam leaks.

- Safety Check: Double-check all screws. Manually rotate the flywheel to ensure the valves open and close at the right time (timing is usually pre-set in kits).

- Firing Up:

- Fill the boiler with distilled water (use the provided syringe/funnel) to the indicated line. Do not overfill.

- Add fuel (usually solid alcohol or liquid alcohol) to the burner lamp.

- Light the burner and place it under the boiler.

- The Launch: Wait for the water to boil (usually 2-5 minutes). Once you see steam trying to escape or hear a hiss, give the flywheel a gentle flick. The engine should roar to life!

Safety Tips:

- Always wear eye protection.

- The boiler and pipes get very hot. Do not touch them during operation.

- Perform your test run in a well-ventilated area.

7. Conclusion

From the mines of the 1700s to the model steam engine on your desk today, the steam engine remains a testament to human ingenuity. Grasping how a steam engine works gives you a deeper appreciation for the technology that built our modern world.

Ready to become an engineer in your own home? Explore our collection of steam engine kits at EngineDIY. Whether you are a beginner looking for a simple build or an expert seeking a complex V4 engine, we have the perfect kit to ignite your passion.

8. FAQs

Q: Is it safe to build a DIY steam engine at home?

A: Yes. Most steam engine kits are designed with safety valves and operate at low pressures suitable for hobbyists. As long as you follow the instructions and treat the burner with respect, it is a safe and rewarding hobby.

Q: What fuel do model steam engines use?

A: Most desktop models use clean-burning fuels like liquid alcohol (ethanol), solid fuel tablets, or butane gas. These provide sufficient heat without creating smoke or toxic fumes indoors.

Q: What is the difference between a steam engine and a Stirling engine?

A: A steam engine is an internal working fluid system (water turns to steam and vents out or condenses). A Stirling engine is a closed-cycle engine that uses permanently contained air or gas, heating and cooling it to create pressure differences. Both are external combustion engines, but they operate on different cycles.