How Do Hit and Miss Engines Work? Unlocking the Secrets of Vintage Power

If you have ever walked through a vintage machinery show or a county fair, you’ve likely heard it: a rhythmic Pop… whoosh… whoosh… Pop!

That is the heartbeat of a hit and miss engine. Unlike the hum of a modern car, these engines have a distinct personality. But exactly how do hit and miss engines work, and why were they designed to skip beats?

In the early 20th century, before electricity reached every farm, these engines were the workhorses of agriculture. Today, they are prized collectibles. Let's dive under the hood (or rather, the open crank) to understand the mechanical genius behind the "hit" and the "miss."

What is a Hit and Miss Engine?

At its core, a hit and miss motor is a type of four-stroke internal combustion engine. However, it differs fundamentally from the engine in your lawnmower or car.

In a modern engine, the spark plug fires and combustion occurs on every single power cycle, regardless of the load. This provides smooth, continuous power.

A hit miss engine, on the other hand, prioritizes efficiency over smoothness. It is designed to fire (hit) only when the speed drops below a certain threshold. If the engine is running fast enough, it coasts (misses) to save fuel. This ingenious design made them the "economy engines" of the 1900s.

The Mechanics: How the Cycle Works

To answer how do hit and miss engines work, we have to look at the three main players: the Flywheel, the Governor, and the Exhaust Valve.

1. The Governor: The Brain of the Operation

The magic lies in the governor system. Usually mounted on the crankshaft or cam gear, the governor consists of weighted flyweights held by springs.

- As speed increases: Centrifugal force pulls the weights outward.

- As speed decreases: Springs pull the weights back inward.

This mechanical movement is physically linked to a latch mechanism that controls the engine's valves.

2. The "Hit" (Power Stroke)

When the engine is under load (like pumping water) and the RPM drops, the governor weights retract. This disengages the latch on the exhaust valve.

- The intake valve opens (usually by atmospheric suction).

- Fuel and air are drawn in.

- The piston compresses the mixture.

- Bang! The spark plug fires.

- The explosion drives the piston down, spinning the massive flywheels. This is the "Hit."

3. The "Miss" (Coasting)

This is where the unique hit n miss engine sound comes from. Once that power stroke accelerates the engine, the massive flywheels build up momentum.

- The speed increases, causing the governor weights to fly outward.

- The governor pushes a latch that locks the exhaust valve in the open position.

- With the exhaust valve stuck open, the piston moves up and down freely with no compression and no suction. No fresh fuel is drawn in.

- The engine simply coasts on the momentum of the flywheels. This is the "Miss."

It will continue to "miss" until friction or load slows the flywheels down enough for the governor to reset, triggering another "hit."

Image Alt Text: Diagram showing how a hit and miss engine governor controls the exhaust valve.

AI Image Generation Prompt: Technical illustration of a vintage hit and miss engine, side profile, highlighting the centrifugal governor and flywheel, detailed mechanical drawing style, sepia tone background.

Why "Hit and Miss"? The Economy Factor

You might see these machines referred to as an economy hit miss engine. This wasn't just a marketing term; it was a necessity.

In the 1910s and 1920s, fuel delivery was difficult in rural areas. Farmers needed an engine that wouldn't waste a drop of gasoline or kerosene. By coasting through several cycles without firing, these engines ran incredibly cool and consumed significantly less fuel than a throttle-governed engine, which fires constantly but throttles the air intake.

Key Characteristics:

- Heavy Flywheels: They store kinetic energy to keep the engine spinning during the "miss" cycles.

- Low RPM: Typically running between 300 to 600 RPM.

- Open Crank: Most parts are visible and easy to repair (though they require manual oiling).

Modern Hobbyists and DIY Builds

While no longer used for commercial irrigation or grain milling, the hit and miss engine has found a second life among hobbyists.

Understanding how does a hit and miss motor work is a rite of passage for many engineering students and model builders. Today, you don't need a barn find to experience this technology. Many enthusiasts build scale models using DIY kits.

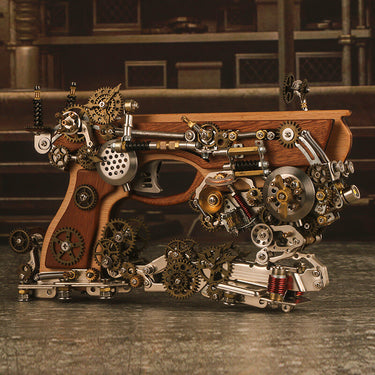

These kits (often available from specialty retailers like EngineDIY) allow you to assemble a fully functional, miniature gas-powered engine. It is a fantastic way to see the governor action up close on your workbench.

Image Alt Text: A small scale DIY hit and miss engine model kit assembled on a workbench.

AI Image Generation Prompt: Photorealistic close-up of a miniature brass and steel hit and miss engine model sitting on a wooden desk, soft lighting, depth of field focused on the spark plug and gears, engineering tools in background.

The Ultimate STEM Teaching Tool: Physics in Motion

Beyond hobbyists, the hit and miss engine has found a new home in classrooms and engineering labs. In an era where modern technology is often sealed inside "black boxes" or hidden under plastic engine covers, these vintage machines offer a refreshing transparency.

Educators use hit and miss motors as perfect visual aids for STEM (Science, Technology, Engineering, and Mathematics) learning. Because of their open-crank design and slow operating speeds, students don't just read about the internal combustion cycle—they can watch it happen in slow motion.

What Can Students Learn?

- Mechanical Feedback Loops: The governor system is one of the earliest and clearest examples of automation and feedback control. Students can physically see how the engine "senses" its own speed and self-regulates.

- Inertia and Kinetic Energy: There is no better way to explain the concept of stored energy than watching a heavy flywheel keep a hit miss engine spinning during the "miss" cycles.

- The Otto Cycle: By observing the valve movements and the spark timing, the four strokes (Intake, Compression, Power, Exhaust) become easy to distinguish, unlike in high-speed modern engines.

Whether it is a restored antique or a transparent model kit, these engines turn abstract physics concepts into tangible, clicking-and-popping reality.

Summary

The hit and miss engine is a marvel of mechanical simplicity. By using a centrifugal governor to physically lock the valve open, it achieves speed regulation without complex electronics or carburetors.

- Hit: Speed is low -> Governor releases latch -> Engine fires.

- Miss: Speed is high -> Governor locks latch -> Engine coasts.

Whether you are restoring a 100-year-old farm relic or building a desktop model, the satisfaction comes from that rhythmic, unpredictable sound of mechanical history coming to life.

FAQ

Q: What fuel do these engines use?

A: Historically, they used gasoline, kerosene, or alcohol. Modern models usually run on lighter fluid or standard gasoline mixed with oil.

Q: Why are the flywheels so heavy?

A: Since the engine doesn't fire on every turn, the heavy flywheels carry the momentum to keep the crankshaft turning during the "miss" cycles.